Rapid prototyping is at the heart of any agile project, allowing the product team to develop and test design ideas quickly and cheaply. Cheaper and more advanced additive manufacturing coupled with 3D scanners and CAD software has powered the rise of RP by letting product teams create models rapidly and then print high-fidelity prototypes for testing.

So let’s get into it and look at 3D scanning and rapid prototyping.

What is Rapid Prototyping?

In a nutshell, rapid prototyping is a process used in product development to create a physical design model quickly. Product teams do this to test the parts’ functionality and design and help finalize the final specifications. Typically, there are three steps: prototyping, testing, and refining, which are repeated till the prototype achieves its requirements.

How Does Rapid Prototyping Save Time and Money?

Traditional methods of creating a physical model, such as creating a mold or casting, can be expensive and time-consuming, as they often require specialized equipment and materials. Rapid prototyping reduces the development time and project cost by allowing product teams to prototype, test, and refine their design quickly. This is mainly possible due to the localized manufacturing ability given to product teams by 3D printers and scanners.

Other benefits include making it easier to identify and fix problems, which greatly helps increase the chances of the final product working as intended. It also helps to reduce the risk of a project by making it easier to test untried new designs.

How Do 3D Scanners Help the Process?

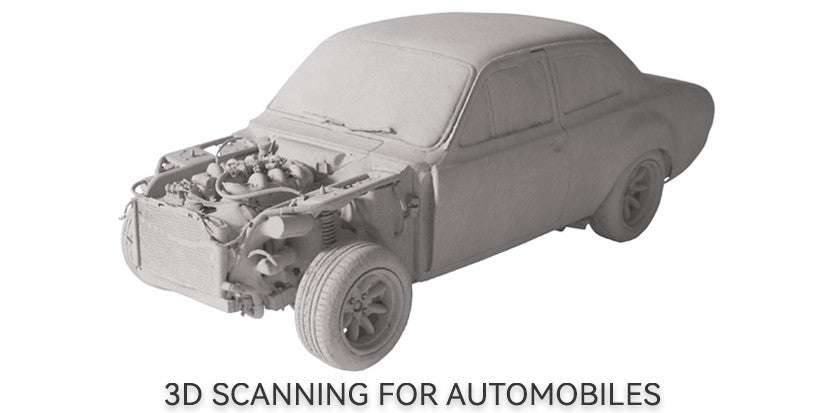

The role of 3D scanners in rapid prototyping is to capture the physical attributes of an object and convert them into digital formats ready for CAD software. Speed is one of the main advantages of using a 3D scanner in rapid prototyping. With 3D scanning, the process is much faster, as the scanner can capture the necessary data in a matter of minutes rather than tens of hours with manual measurements.

Accuracy is another key advantage of using a 3D scanner in rapid prototyping. The scanner can capture an object’s exact dimensions and shape, ensuring that the resulting 3D model accurately represents the original. This level of accuracy is essential in product development, as it allows designers and engineers to identify and correct any issues before the product goes into production. And with the help of a Revopoint 3D scanner, rapid prototyping is even more cost-effective due to the affordability of the POP 2, MINI, and RANGE 3D scanners.

What Else Do I Need?

Well, of course, you need an additive manufacturing method to produce your prototypes, CAD software for design, and, ideally, a customer-centric testing group so you can get constructive feedback. And that’s about it, as it’s the simplicity of the requirements that make 3D scanning and rapid prototyping effective.

Hinterlasse einen Kommentar

Diese Website ist durch hCaptcha geschützt und es gelten die allgemeinen Geschäftsbedingungen und Datenschutzbestimmungen von hCaptcha.