Reverse engineering has been going on for thousands of years. A classic example is ancient Rome reverse engineering a Carthaginian ship they found during the first Punic war (264–241 BC). The Romans used their theft of Carthaginian shipbuilding knowledge to build an effective navy that ultimately helped them become victorious over the Carthaginians. Hmm, it seems like reverse engineering can be pretty handy, and I bet that the Romans would have loved to use a 3D scanner to do it.

So let’s take a look at what reverse engineering and 3D scanning is and why it is done.

What exactly is reverse engineering?

In a nutshell, reverse engineering is taking something (could be any object, enormous or tiny) and then deconstructing it, studying its structure, how it works, and how it was made to understand its design. This can be quite a painstaking days-long process of manually measuring everything, drawing diagrams, and double-checking that the information is correct.

Fortunately, these days you can get it done much faster with the help of 3D scanners. They enable accurate 3D models to be created quickly and imported into CAD software for transformation into a working manufacturing model in only a few hours, vastly cutting down on time spent acquiring data and significantly speeding up the entire process.

Now, let’s take a look at some reverse engineering applications.

Legacy Equipment

You might be surprised to discover that many machines and essential infrastructure are running on legacy technology because, as the saying goes, “if it ain’t broke, don’t fix it.” But even these venerable machines occasionally need replacement parts to keep them chugging along.

And as you might imagine finding replacement parts can be challenging. And being out of action for weeks waiting around for measurements and prototypes isn’t an option either. However, with a 3D scanner, machine parts can be scanned and reproduced quickly, getting the machine back in action as soon as possible.

Modifying Equipment

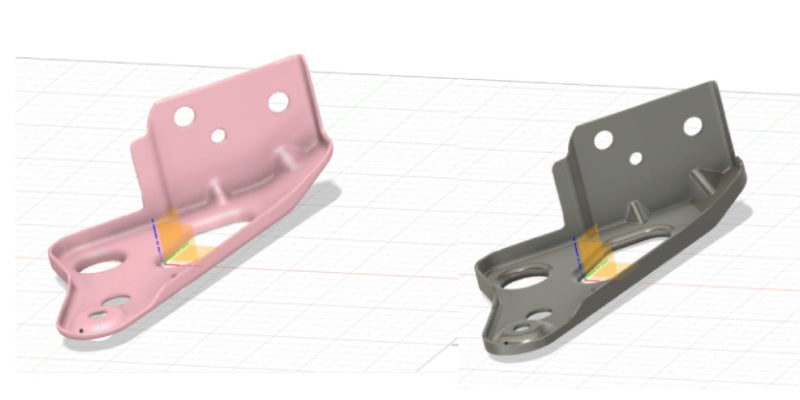

Sometimes, the design is nearly perfect except for one thing that messes up your workflow. Contacting the manufacturer and asking them to create a custom piece probably won’t offer any joy, or it’ll be too costly for one-off production. But with a 3D scanner on hand, you can do it all yourself, scanning the original part, modifying it to your own specifications, and finally getting your workflow back on track.

Product Development Research

Understanding how your competitors make their products is invaluable in helping drive your product design forward by learning what worked well and what didn’t for them. Then understanding why that’s the case makes creating your own better product much easier. However, straight-up copying their work and selling it will land you in legal trouble for IP theft.

What 3D scanner should I get to do this?

Well, this depends on the size of the thing you want to reverse engineer, as 3D scanners are optimized for scanning specific sizes of objects. So check out the table below to see which 3D scanner suits you.

| Product Name | Object Size | Accuracy | Point Distance |

|

Revopoint MINI |

Small-sized objects like jewelry, small cogs, screws, etc. | Up to 0.05mm | Up to 0.5mm |

| Revopoint POP 2 | Medium-sized objects like gearboxes, mechanical parts, tail lights, etc. | Up to 0.1mm | Up to 0.1mm |

| Revopoint RANGE | Large-sized objects like cars, bikes, furniture, etc. | Up to 0.3mm | Up to 0.3mm |

In this day and age, where efficiency and speed are cornerstones of modern business, getting your 3D models created quickly and on budget with the help of reverse engineering and 3D scanning is essential to remain competitive.

Laisser un commentaire

Ce site est protégé par hCaptcha, et la Politique de confidentialité et les Conditions de service de hCaptcha s’appliquent.