MINI use industrial-grade blue light for higher accuracy

Blue light is widely used in industrial-grade 3D scanners, but the cost often makes ordinary consumers flinch. For this reason, Revopoint has introduced the brand new MINI series, which adopts industrial-grade blue light technology at an affordable price. Revopoint MINI is the first affordable blue light 3d scanner.

Blue light scanning has a strong anti-light interference ability, and can also carry out high-precision scanning in complex light environments. Blue light has higher accuracy than white light and infrared light. Through its advantages, blue light covers a wider range of fields, industry in particular, and has broader applicability.

The Revopoint MINI 3D scanner projects ultra-high-resolution blue light and has a strong ability to resist ambient light. The details can be pretty well captured and shown in the 3D digital model. When the industrial-grade blue light is used, the Revopoint MINI 3D scanner offers an affordable price for consumers.

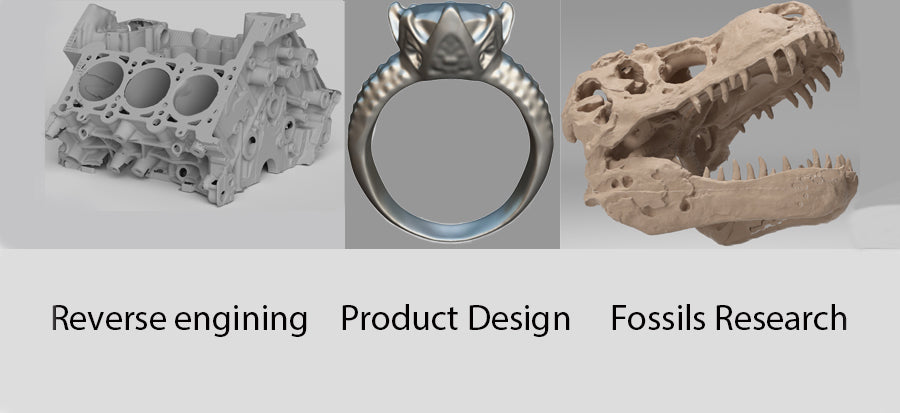

The MINI 3D scanner uses class 1 blue light, which is harmless to the human body and can be scanned directly on the skin making it safe and user-friendly for all possible applications. MINI can be used for reverse engineering, fossils and cultural relics 3D modeling, jewelry design, medical application, 3D animation production and modeling, and quality inspection.

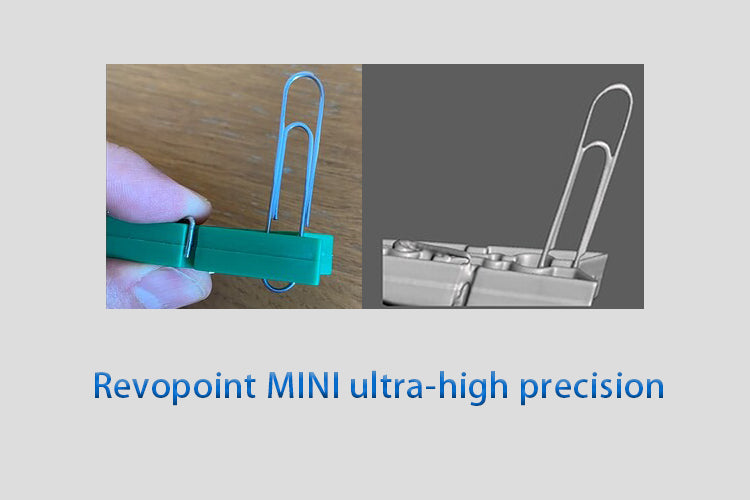

Revopoint team aims to create the 3D scanner with ultra-high precision technology to bring the users a better experience at an affordable price. The MINI 3D scanner’s industrial-grade precision of 0.02mm allows even the tiniest parts to be accurately scanned and presented. MINI uses upgraded projection technology to capture the data of objects in a short time. The output model has a high density of point clouds with a 0.05mm point distance.

There is a showcase shared by @dlfodaro from Revopoint’s forum, who is a professional art conservator and for several years has been using 3D technologies in work on the conservation of Cultural Heritage. He/she tested MINI to see if it could pass the challenge —— of scanning a paperclip, of which wire diameter is 1.21mm. Here is the result.

For the super thin and high reflective object, it will be a big challenge to the equipment. Revopoint MINI 3D scanner achieves a high level of precision, which helps scan this paperclip successfully.

Revopoint MINI is very easy to use

The MINI 3D scanner can also be used for garage kit reproduction, miniature 3D model making, and other fields and instances in which obtaining detailed high-precision models is necessary. MINI is compact and portable, weighing only 160g, allowing it to fit into your pocket easily. Everywhere you go, MINI goes. MINI requires only one cable for charging and data transfer. Hassle-free, there is no need for preliminary preparation. You can connect the MINI to a computer, smartphone, or power bank and carry out your scanning work anywhere, anytime.

Here is another case from @dfodaro, he/she used MINI to scan an ancient gilded frame.

He/she left the comment “I tested the MINI Revopoint on a gilded frame…… The achievable resolution is amazing. Furthermore, I did not carry out any surface treatment (Aesub spray).”

The MINI 3D scanner well presented the pretty complex features in the frames and restored the cracks between those complicated patterns. When MINI is designed to work as a handheld and turntable scanner, people can scan and get high-precision 3D models in a series of scenarios such as the ancient gilded frame.

There are three Revopoint’s software to help get better-scanned model

Revopoint MINI 3D scanner captures the high precision 3D model and the software Revo Studio plays an important role as well, which is released by Revopoint team. Back on the paperclip case, the 3D models were merged by Revo Studio, which supports two ways of alignment: by feature or by marker points. Then the clear 3D model of this tiny object was presented.

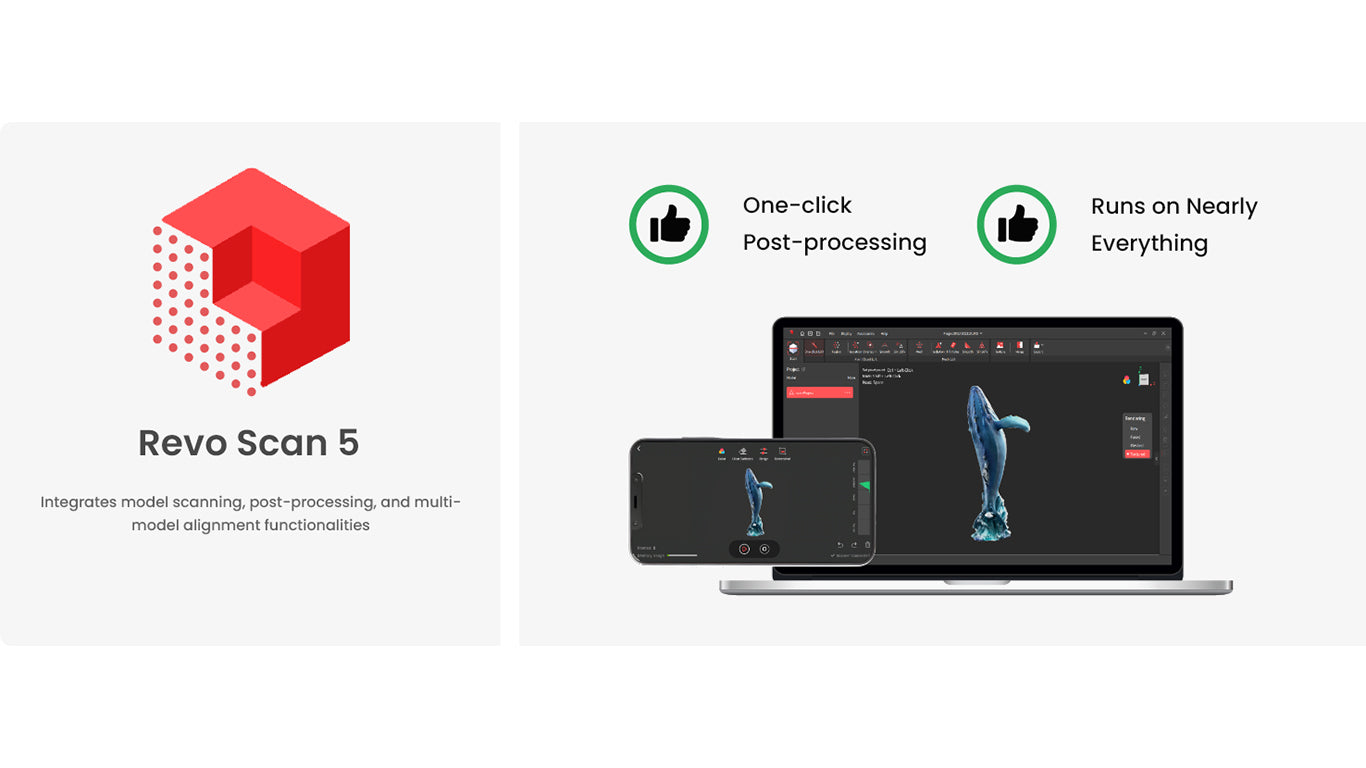

Revopoint has developed three powerful software for obtaining an even more perfect model: the scanning software Revo Scan, the professional model editing software Revo Studio, and the calibration software Revo Calibration. Revo Scan and Revo Studio can be utilized at different stages of the scanning process to help create a high-precision scan that captures every inch of detail the user seeks to include.

Revopoint software/App comes with a simple and clear UI design, letting you manage the operation efficiently. It supports three common 3D file formats (PLY, OBJ, and STL) and is compatible with major professional application software. It is ideal for users to achieve a convenient and efficient cross-platform workflow.

Revo Studio is a self-developed 3D model editing software. It possesses ‘Clip’, ‘Mesh’, ‘Simplify’, ‘Fill Hole’, and ‘Alignment’ features. You can edit the point cloud files and mesh models. In addition, you can further enhance your creativity by fusing and aligning multiple models.

Revo Calibration is a calibration software designed for portable 3D handheld scanners. With Revo Calibration, you can re-calibrate the scanner and reset the camera’s internal parameters. It guarantees the precision of the MINI remains the same as the factory standard, ensuring you a high-quality and accurate 3D model every time.

The tester @dfodaro seriously regards accuracy as an important matter because of his profession as an art conservator and several years of using 3D technologies on the conservation of Cultural Heritage. He/she has tested with small sculptures with small features.

This Indian sculpture is 3cm tall. Here is another example of a small object of 9 cm with small and intricate features. After point fusion, meshing, and minimal editing, the final result can be seen below.

Then he/she scanned a small beautiful Bacchus bronze head of 12cm, saying “The small bronze sculpture has a richly patterned surface, with fine details. The surface was coated with a thin layer of a 3D scan spray (Aesub). It is a product that leaves the surface intact, and it is not necessary to remove mechanically, but vanishes after a few hours.” After processing in Revo Studio, the result can be seen below.

With the help of blue light technology, intelligent algorithm and software, the MINI 3D scanner makes the 3D model extremely precise and detailed, helps people quickly achieve accurate 3D data reconstruction and saves 80% of the time and cost in creating 3D models. It is an ideal device that can scan objects with various shapes and features for all kinds of 3D modeling needs.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.